STORIMPEX Import and Export GmbH stands for high quality asphalt pavements that preserve both environment and resources. We develop and distribute innovative additives for asphalt production. Our enterprise consults customers worldwide with expertise and experience in all technical aspects of road construction, as well as in the production and processing of asphalt.

A groundbreaking development project of the STORIMPEX Import and Export is a maximum-recycling procedure for road restoration, in which all layers of the road surface are reprocessed as good as new. Due to a patented additive combination of softeners and hardeners, our procedure requires almost no new resources therefore saving both CO2 emissions as well as overall costs. We have renovated many roads and areas in Germany using recycled asphalt with great success. Another proven product is STORELASTIC. STORELASTIC allows for a resource-friendly use of rubber granulate taken from used car tires for asphalt production.

STORIMPEX was awarded the environmental award "BILD-Umweltheld Hamburg" for optimal implementation of the closed-loop recycling thought that is formative for environmental protection.

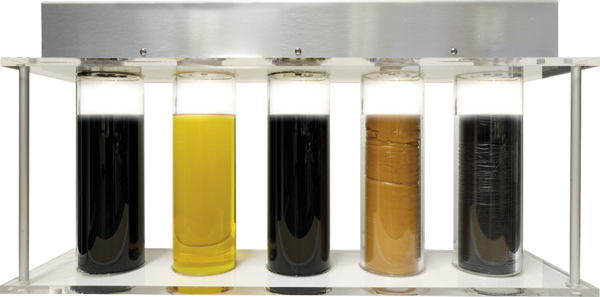

STORELASTIC is a pretreated rubber granulate that can be used for modifying asphalt and bitumen in both dry- and wet-processing.

STORELASTIC drastically improves low temperature properties as well as heat resistance of the modified asphalt. Compared to polymerically modified asphalts, asphalts modified with STORELASTIC are characterized by a significantly higher weather resistance and therefore longer durability, as well as a superior noise reduction.

STORELASTIC can be applied with all common mixtures:

* Asphalt base binders and cover layers

* Stone mastic asphalt

* Open-pored asphalt

* PMA (Porous Mastic Asphalt)

* Noise optimized asphalts (p.E. LOA D, SMA LA)

* Thin layers in hot application (DSH, DSH-V)

* SAMI-Overlay (Stress Absorbing Membrane Interlayer)

Field of use ranges from low frequented roads to highly stressed asphalt constructions such as highways or industrial areas. The STORELASTIC percentage averages between 10 – 20 M.-%, depending on the application and binder content.

STORELASTIC is a combination of rubber granulate, a special oil and Sasobit®. The used rubber granulate is grinded ambiently, very smoothly and consists of a predefined mixture of truck and passenger car tires. Due to the pretreatment of STORELASTIC with a special oil, no ripening time of the mixture is necessary. It can be distributed and assembled right after production. The pretreatment with oil furthermore minimizes the absorption of readily-volatile components of the bitumen in the rubber granulate. The effect: Aging of the used bitumen is drastically reduced, the asphalt doesn't embrittle early and premature thinning or pull-outs are avoided. Rubber increases the viscosity of the asphalt mixture. By using Sasobit®, a viscosity-modifying additive, STORELASTIC can be produced, assembled and compressed even at low temperatures without problems. This even includes manual assembly. Another positive effect of the temperature reduction is a significant reduction in odor emissions.

ADVANTAGES

* High deformation consistency

* Very good low temperature behavior

* High aging resistance

* Durable

* Noise-reducing

* Environmental friendly

Rejuvenators are softeners that were specifically designed for recycling of excavated asphalt in mixture production. They act regeneratively on the aged bitumen and can even be applied for recycling of polymerically modified mixture, considering the requirements on the elastic properties.

Even with heavily-aged binding materials and with a high added amount of recycled asphalt, the rejuvenators enable the production of high-quality mixtures.

ADVANTAGES

* Regenerating of the aged binding material

* Exact reduction of the softening point RuK

* Cost Efficiency

* Binding Material Savings

* Protection of natural resources

Our additives for maximum recycling were developed for highest possible recycling of excavated asphalt and allow for a recycling rate of asphalt granulate of up to 95%. All STORBIT products are based on a mixture of our STORFLUX rejuvenators with Fischer-Tropsch Waxing of the Sasol Wax GmbH. They act as both softeners (STORFLUX/STORFLUX PLUS) and hardeners (Wax components).

The oxidized binding material is reactivated and heat resistance of the modified mixture is increased without negatively impacting cold temperature properties. Other than with common mixtures, mixture and installation temperature can be reduced by up to 30 °C without negatively impacting processing.

ADVANTAGES

* Recycling rates of up to 95 %

* Reduction of asphalt production temperature by up to 30 °C

* Improved installation properties / compactability of the mixture

* Improved durability

* Storage capability in the bitumen tank

... Nowadays, it is not made sure enough in road construction contracts that the individual asphalt layers on the roads are reused according to their respected initial function...…Nowadays, it is not made sure enough in road construction contracts that the individual asphalt layers on the roads are reused according to their respected initial function ...

... Apart from the protection of resources, such processes offer significant economic advantages through lower cost of material. From an ecological standpoint it is important to mention that a high recycling rate can reduce CO2 emissions by more than 30% ...

...Environment-unfriendly commissioning in the recycling of asphalt for road construction. At the moment, public commissioning in road construction is not acting enough in accordance with the statutes of environmental law ...

... New asphalt for the Mönckebergstraße ... Hamburg’s No. 1 shopping mile receives new pavement – an environmentally-friendly version that was developed in Hamburg and seeks its own ...

... Full recycling method sets standards in sustainability, longevity as well as in environment and resource protection ...

... Major progress that connects ecology and economy in model fashion...

... Innovation: Saving money is no magic! Made possible by a new wax-oil additive that is added to the carefully milled old asphalt in the heating process. The result: a regenerated pavement that is just as stable and flexible as a new one, but 30% cheaper...